#InduTech Pillars

Industry 4.0

Internet of things (IoT), Cyber-physical systems, Vertical and horizontal process integration, Big Data, Fog & Edge computing, Virtual reality, Sensors & Monitoring.

GreenTech & CleanTech

Energy efficiency, storage solutions, and innovative technologies that promote a sustainable energy future. Climate change and the global demand for clean energy sources.

Robotics & AI

Industrial robotics, Artificial intelligence, Machine Learning, Automation of maintenance, High risk interventions on industrial processes, Visual recognition technologies, Drone technology.

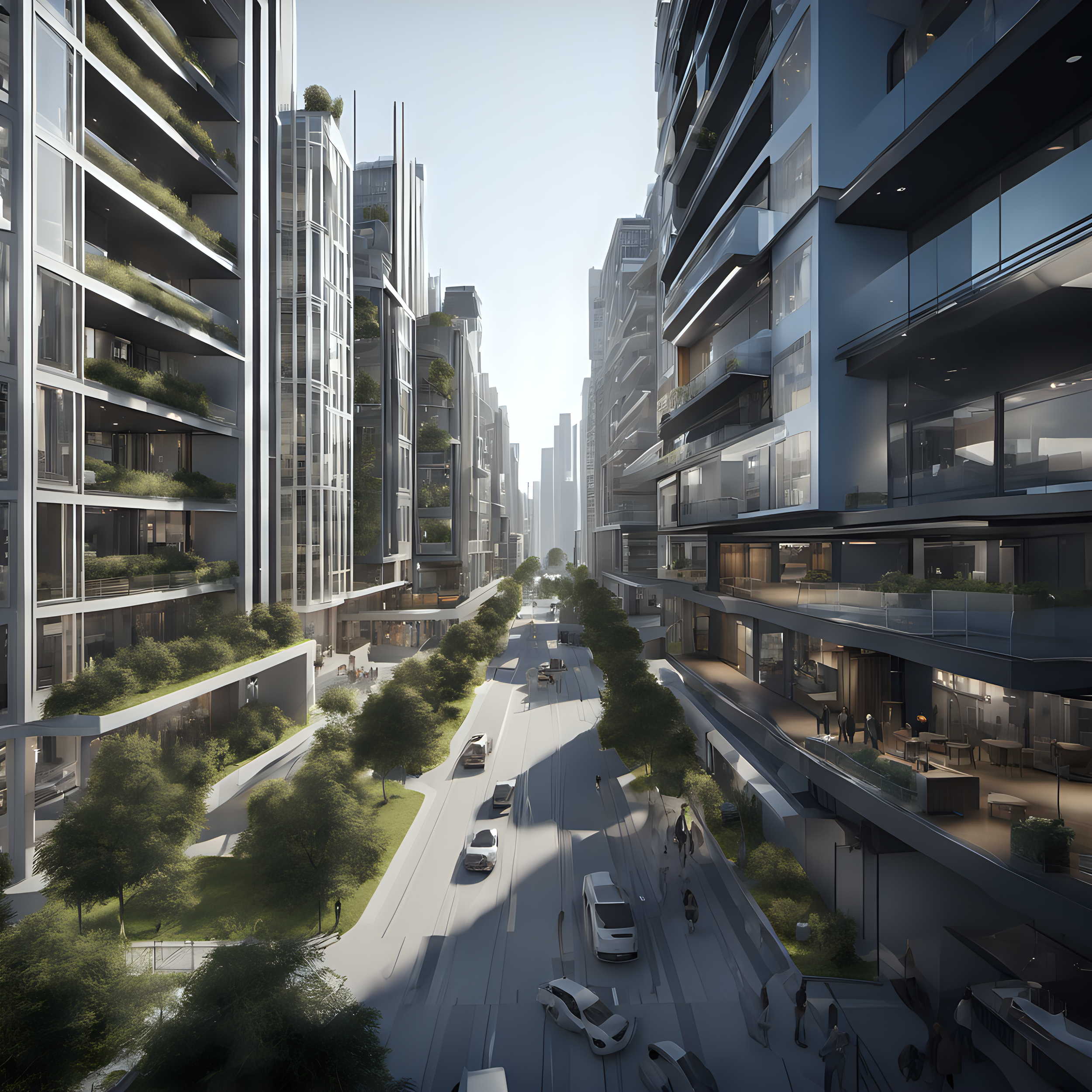

Innovative Construction Technologies

New construction techniques, materials, and digital tools to create smarter, safer, and more sustainable buildings and infrastructure. Modular construction, green building materials, and digital twins for better project management.

Advanced Safety and Security Technologies

AI, machine learning, IoT, and other cutting-edge technologies to improve safety and security in various domains. Cyber security solutions, workplace safety innovations, and technologies that enhance public safety and emergency response capabilities.

Sustainable Mining and Resource Efficiency

Technologies and methodologies for responsible mining practices, resource conservation, and the circular economy. Innovations that reduce environmental impact, improve resource management, and ensure the ethical sourcing of materials.

Advanced Mobility

Transportation and logistics industry through AI, IoT, autonomous vehicles, and sustainable practices. Innovations aimed at reducing carbon footprints, enhancing supply chain efficiency, and promoting green mobility solutions.

Advanced Manufacturing

Additive manufacturing, Rapid prototyping, Metal powders for 3D printing, Nano-coatings, New design approaches, Material properties.

Smart Engineering & Processes

3D scanning technology, Visual capturing technology, Reverse engineering methods, Concurrent engineering, Big Data management, Predictive Maintenance

Got an idea? Reach us now!

You are a startup -> Check our calls to see if your technology fits one of our corporates challenges.

You are a corporate -> We can scout innovatives solutions for you that can answer one of your current challenges.